The history of racing is deeply intertwined with the evolution of chassis design, which has played a crucial role in enhancing both performance and safety in motorsports. From the earliest days of automobile racing to the cutting-edge technology used in modern race cars, the continuous progress in chassis development reflects the sport’s relentless pursuit of speed and efficiency. Racing chassis have transitioned from simple, rigid frames to complex structures designed to optimize aerodynamics and weight distribution.

In the early years of racing, the primary focus was on maximizing engine power without much consideration for the chassis itself. As competition intensified, engineers began to recognize that a well-designed chassis could significantly influence a vehicle’s handling and speed. This understanding sparked innovative approaches to materials and design, resulting in chassis that could withstand extreme conditions while empowering drivers to push the limits of their cars.

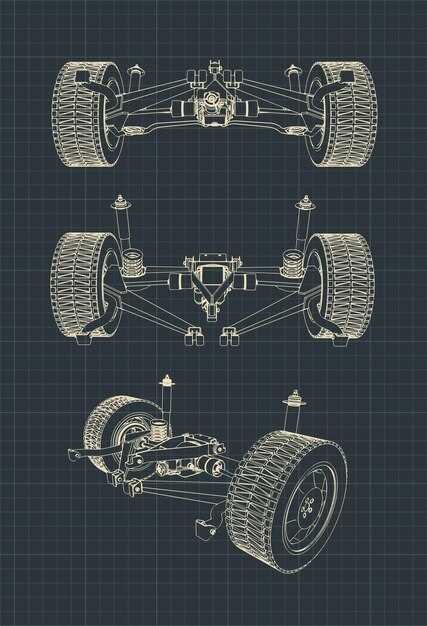

Throughout the decades, various designs–from the backbone chassis to the monocoque structure–have emerged, showcasing the evolution of racing technology. Each phase marks a significant milestone in the quest for performance, as teams adapt to new regulations and the ever-changing dynamics of racetracks. The chassis not only serves as the foundation of the race car but also embodies the spirit of innovation that keeps motorsports at the forefront of engineering excellence.

Influence of Material Science on Chassis Development

The evolution of race car chassis design is profoundly influenced by advancements in material science. Over the years, the choice of materials has shifted from traditional steel to lightweight composites and alloys, drastically changing the performance characteristics of racing vehicles. This transition has allowed engineers to develop chassis that not only reduce weight but also improve structural integrity and aerodynamic efficiency.

Initially, steel was the primary material used for chassis construction due to its availability and strength. However, as racing technology evolved, the limitations of steel became apparent, particularly in terms of weight and flexibility. The introduction of aluminum significantly altered chassis design by providing a stronger and lighter alternative, enabling manufacturers to optimize performance while maintaining durability.

In recent years, carbon fiber has emerged as a revolutionary material in racing chassis design. Its high strength-to-weight ratio allows for innovative designs that enhance both speed and handling. The adoption of carbon fiber reinforced plastics (CFRP) has enabled teams to push the boundaries of performance, resulting in agile and resilient chassis that withstand the extreme conditions of competitive racing.

Moreover, advances in material science have facilitated the development of hybrid materials that combine the beneficial properties of different substances. These materials can be engineered to provide tailored mechanical properties, resulting in chassis that are not only lightweight but also capable of absorbing impact and dissipating forces effectively.

The influence of material science on chassis development continues as researchers explore novel materials and manufacturing techniques. Innovations such as 3D printing and nanomaterials hold promise for further revolutionizing chassis design, allowing for more complex geometries and improved performance metrics in racing. Overall, the integration of advanced materials has transformed chassis design, leading to safer, faster, and more competitive racing vehicles.

Impact of Aerodynamics on Chassis Geometry

The history of race car chassis design has been significantly influenced by advancements in aerodynamics. Over the decades, understanding airflow and its effects has become crucial in shaping chassis geometry. Designers have continually adapted the structure and materials of the chassis to enhance aerodynamic efficiency, paving the way for improved speed and handling on the track.

Initially, race cars featured simplistic chassis designs, prioritizing weight reduction over aerodynamic considerations. However, as the sport evolved, engineers recognized that streamlined shapes could reduce drag and increase downforce. This realization led to the integration of aerodynamic elements directly into chassis geometry, such as side skirts, diffusers, and wings, which are designed to manipulate airflow around the vehicle.

The introduction of computer-aided design and computational fluid dynamics has revolutionized how aerodynamics is applied to chassis construction. Engineers can now simulate airflow over different chassis shapes, enabling them to optimize designs for maximum aerodynamic efficiency. This has resulted in chassis that are not only lighter and stronger but also more effective in generating downforce and stability at high speeds.

Modern race cars exhibit highly sophisticated chassis geometries, reflecting a deep understanding of the principles of aerodynamics. The design of the chassis is now intrinsically linked to aerodynamic performance, with features such as active aerodynamics that adjust based on speed and track conditions. This evolution in design has not only improved lap times but has also increased the safety and reliability of race cars.

In conclusion, the impact of aerodynamics on chassis geometry remains a defining factor in the evolution of race car design. The continuous quest for speed and performance has driven innovations that intertwine structural design with aerodynamic principles, marking a significant chapter in the history of motorsport engineering.

Technological Innovations and Their Role in Chassis Engineering

The history of racing is marked by constant evolution, particularly in the design and engineering of the chassis. Technological innovations have played a crucial role in enhancing performance, safety, and overall efficiency of race cars. Starting from the early days of motorsport, chassis design has transitioned from wooden frames to sophisticated composite materials, reflecting the rapid advancement in engineering and technology.

Lightweight Materials have become a significant focus in chassis engineering. The introduction of materials such as carbon fiber and aluminum alloy has reduced weight while maintaining strength and rigidity. These innovations allow for improved speed and maneuverability on the track, giving teams a competitive edge.

Aerodynamics has also revolutionized chassis design. The integration of aerodynamic principles has led to the development of streamlined shapes and features such as wings and diffusers. These elements enhance downforce and reduce drag, enabling race cars to achieve higher speeds during competitions.

Advancements in computer-aided design (CAD) and simulation software have transformed the way engineers approach chassis design. These tools allow for precise modeling and testing of various design concepts, ensuring optimal performance before physical prototypes are built. Such innovations have significantly reduced development times and costs associated with the racing chassis.

Moreover, safety innovations have had a profound impact on chassis engineering. The implementation of safety features such as crash structures, roll cages, and energy-absorbing materials have improved driver protection significantly. These enhancements not only meet regulatory requirements but also reflect a growing commitment to ensuring the safety of drivers during races.

In conclusion, technological innovations have been pivotal in shaping the history of racing chassis design. From materials and aerodynamics to computer modeling and safety features, these advancements continue to push the boundaries of what is possible in motorsport, paving the way for future developments in chassis engineering.